Recommended for You

- Choosing a selection results in a full page refresh.

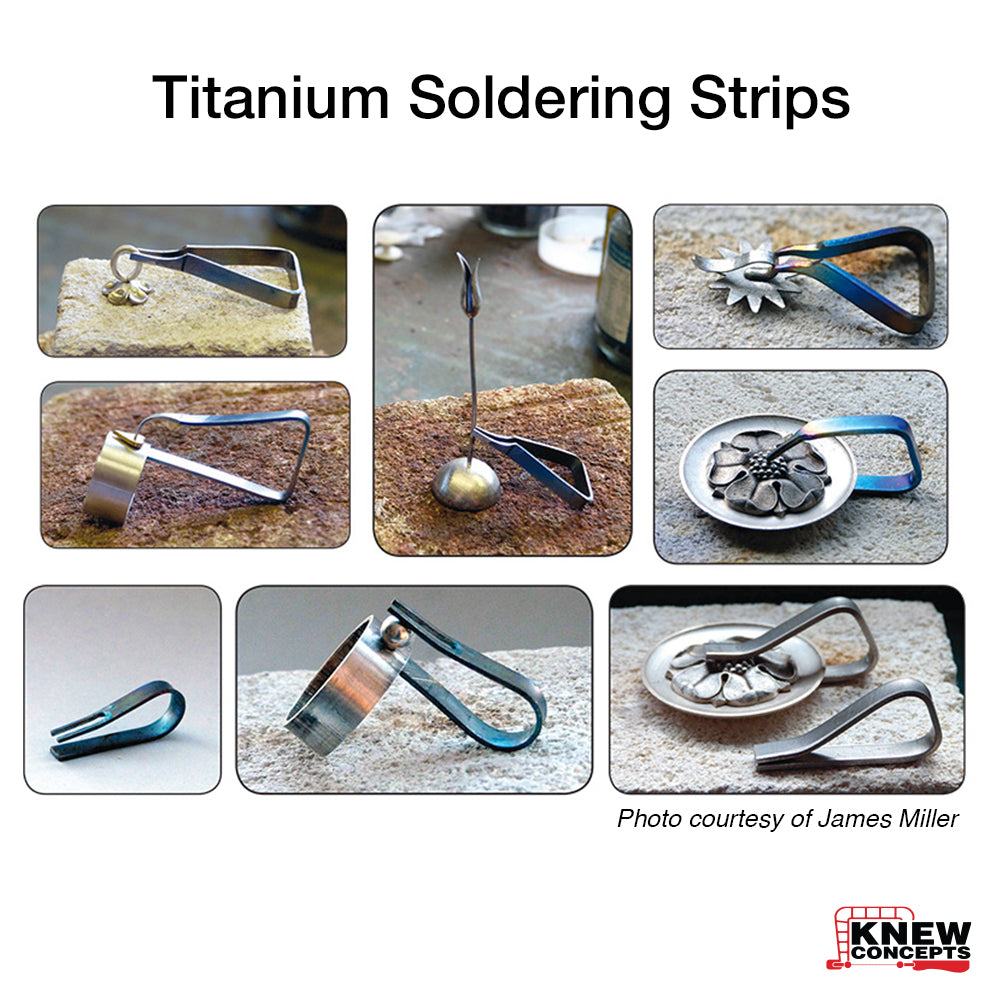

Inspired by British Master Goldsmith James Miller, these titanium strips can be easily bent into a wide range of specialized custom clamps for jeweler’s hard soldering operations.

Download how to bend and shape clamp instructions.

Titanium has several advantages over traditional steel clamps when it comes to soldering. Solder doesn’t stick to it. Enamel doesn’t stick either. It stays strong when red hot. It doesn’t erode and flake away at heat, so your clamp tips can be smaller. Most importantly, titanium doesn’t transfer heat nearly as quickly as steel clamps, so it interferes with nearby joints less than steel clamps do.

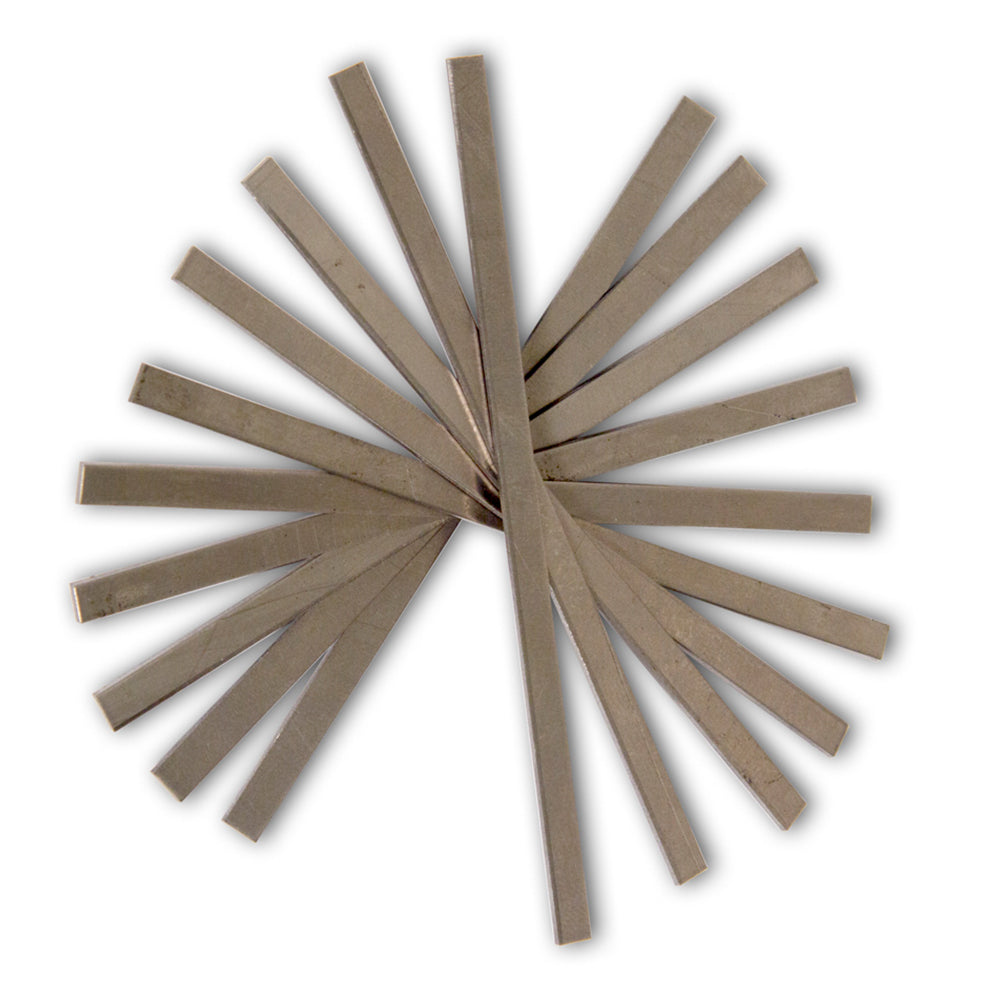

These clamps are sold in a pack of 10 “blanks” as straight 4" strips, to allow you to bend your own ideal clamp designs. Each soldering situation is different, and while there are a few basic designs that we illustrate in the how to bend and shape clamp instructions, every jeweler is different, and each solders in their own unique way, and will need clamps customized for their own personal style, or unique need. The titanium strips are fully annealed, and can be bent and filed to suit in minutes.

To date, we’ve found several uses for them:

“We are dedicated to helping you pursue your work and your passion for well-made tools that bring pleasure to the task. Our products may feel luxurious to use, but they are never extravagant, as they are designed and made with you and your needs foremost and are made to last a lifetime. Reward yourself for all of your hard work!”

© 2026, Knew Concepts | Website design by JSG Design Studio, Santa Cruz, CA. All Rights Reserved.